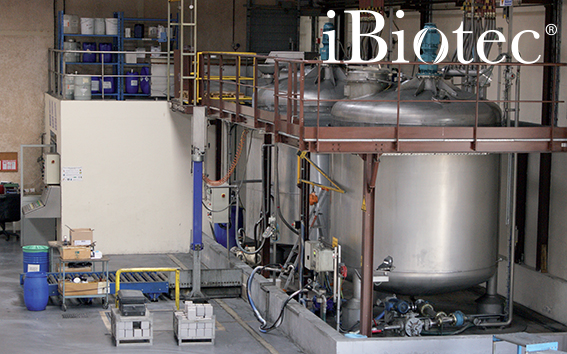

Site of Saint-Rémy de Provence

iBiotec Tec Industries production site

iBiotec®

Tec Industries®Service

Based on the principles of the following current standards:

ISO 9001 - ISO 14001 - ISO 45001

Integrated Management System

ISO 14040 - Life Cycle Assessments

ISO 26000 - Social Responsibility

Research & Development:

a significant asset!

|

Our R & D team, engineers and technicians combine to contribute to the whole process thanks to their varying specialist fields. Lubrication, tribology, metalworking, demoulding, degreasing, alternative solvents, cleaning, detergency and anti-corrosion. The design process involves listening and responding to our Customers to enable us to perfectly define a solution which suits their needs. Furthermore, we organise all our services, in order to ensure we are able to respond quickly in line with their expectations. Our regional managers responsible for technical training have extensive experience within the industry and remain close by to our clients to provide ongoing advice and recommendations when needed. |

|

|

|

Related services Assistance in drawing up technical specifications Chemical analysis Testing laboratory Regulatory assistance Technical training are all services which we offer every day to our Customers. iBiotec have more than 50 years of experience in the development of special chemicals within the private label industry for some of the biggest European companies. We realise the importance of adapting our specific formulas to the individual processes of each of our Customers |

A managed production process throughout!

|

|

Automated production line

2 manufacturing units with an output of 14,000 liters / hour

3 manufacturing units with an output of 10,000 liters / hour

3 manufacturing units with an output of 6,000 liters/ hour

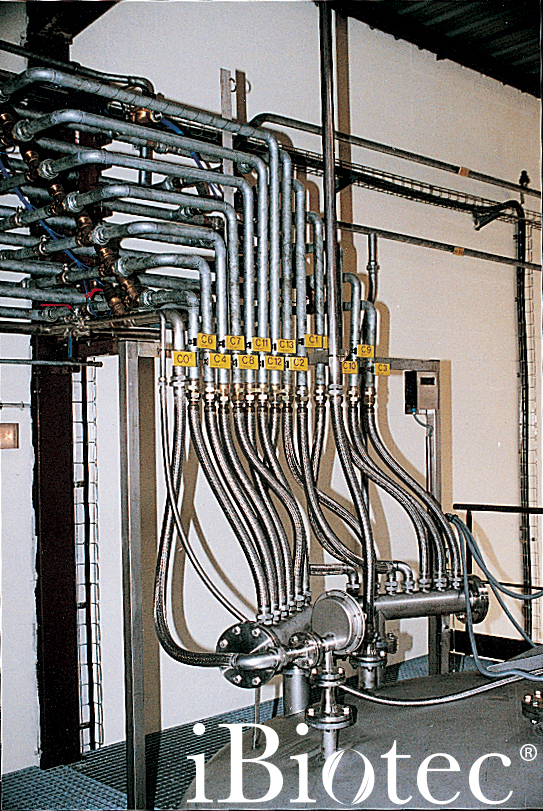

Integrated aerosol packaging process!

Integrated aerosol packaging process!

|

|

| iBiotec is the inventor of an exclusive process for pressurising aerosol containers using ‘gas-impact’ typically associated with the ‘gas-shaker’ technique. Patent 904 0 1968.4. This process makes it possible to use a propellant that falls within any of the following categories: natural, inert, nonflammable, incombustible which is suitable for use in pharmaceutical, medical, bacteriostatic environments as well as those related to foodstuffs with unlimited availability. |

3 fully automated filling lines with a combined capacity of 60 spraycans/minute per machine. iBiotec carries out predictive maintenance at all facilities. |

100% control

|

In accordance with the requirements and specific instructions we receive from our Customers, iBiotec are able to deliver each batch with: a certificate of conformity. an analysis certificate. an analysis report produced by an accredited external laboratory including COFRAC, BPL, in accordance with ISO 17.025. an IR spectrometric result (where product viscosity permits). iBiotec also ensures that all product batches are fully traceable; the batch data is stored for a fixed period of 10 years. |

|

|

A logistics platform that ensures

quick delivery times!

|

|

| Storage of Neutralene® and Bioclean® for bulk consignments or intermediate bulk container deliveries |

8,000 m² of dust-free secure warehouses. All of our products are in stock. With our integrated solution from production to packaging we can replenish stock without delay |

Integrated printing of graphics and decoration!

|

|

iBiotec itself carries out, the printing of all decoration onto the packaging using screen-printing or pad printing methods.

at their Saint Rémy de Provence site.

9 printing lines allow us to print up to 4,000,000 units.

With immediate regulatory compliance.

A specialist range for those operating within networks of specialised distributors or technical merchants.

We also provide packaging in foreign languages suited to the destination providing a practical advantage in the target country.